2021

Syracuse, NY

Designed with Luis Lopez under Professor Kamell

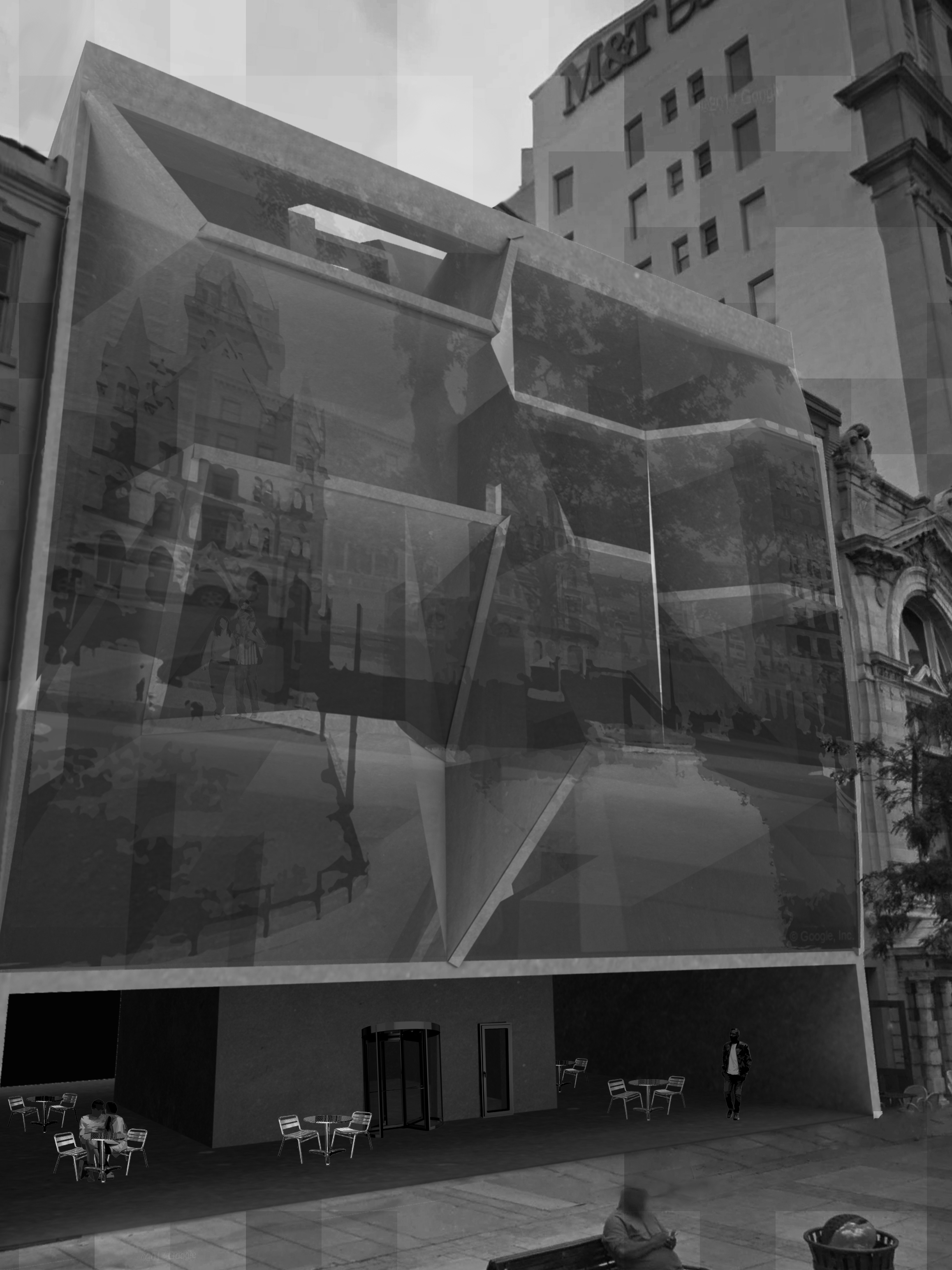

Syracuse has had a long history of ceramic manufacturing and innovation. Syracuse China, one of the leading manufacturers and researchers within the ceramics industry, was based here for over a century. Its closure in 2009 marked the end of over 130 years of production. The Everson museum has one of the largest pottery collections of any museum in the United States, and the Syracuse Ceramics Guild is a thriving community with historic ties to the city. Our proposed project, Syracuse Ceramic, located adjacent to M. Lemp Park on S Warren and E Fayette St, is a housing complex and pottery studio created for retired ceramic workers and hobbyists.

Within architecture, the use of ceramics has transformed from purely structural walls and arches of brick to ornamental facades composed of tile and terracotta. The early use of reinforced masonry as a construction element dates back to the 1800s where Marc Brunel used it in the construction of the River Thames tunnel. Raphael Guastavino sandwiched metal reinforcement in both directions between masonry tile layers to create timbrel vaults. Our proposal explores the use of ceramics through both structure and ornamentation. As one moves through the building, ceramic takes on different roles in space, narrating how the material has been and is used in architectural practice.

Entering the project from M. Lemp Park, a ceramic-tiled plaza reaches out to the park, extending public space to the building’s entrance and creating a landscape of masonry emerging from the ground. The underground pottery studio is composed of rough hewn, dramatic Guastavino vaults that create cavernous pottery studios with clear programmatic hierarchies. Towering domes composed of recycled brick break through the ground plane, bringing light and public attention to the potters’ work below. The transition between the upper column grid and the lower catenoid domes utilize reinforced masonry ribs and concrete shell to carry weight to columns.

In the floors above featuring residential space and public amenities, concrete floor slabs are poured over extruded terracotta formwork, while the façade utilizes a terracotta rainscreen cladding. On the ground floor, radiant hydronic tubing is embedded in the large masonry domes, creating thermal masses that heat the lower floors. Trench heating and central HVAC maintain thermal comfort in residential areas. Sustainable passive strategies are also employed throughout the building, as each apartment has a southern exposure with a closed-cavity ceramic louver system where solar radiation can be moderated depending on weather. In addition, ceramic has a low embodied carbon and excellent thermal properties acting as a thermal mass. Along with the kilns, a heat capture system is used to harness the excess heat produced. The ORC, or Organic Rankine Cycle, takes the exhaust heat of the kiln which is routed under the raised terrazzo floor system to the boiler which heats up the water. This heated water then travels to the expander which produces electricity. The water is then transferred to the condenser where it cools down and produces cold air. The cycle continues as water is then pumped back into the boiler to be reheated again.